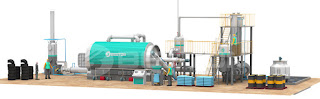

What exactly is a Pyrolysis Plant and the way Does It Work?

A pyrolysis plant converts waste plastic and outdated tires into fuel oil. Waste tires and plastic would be the raw materials in this plant. The plant processes these materials in the reactor to generate fuel which can be used inside the steel wire industry or as diesel in cars.

Pyrolysis plant principle

The key of this type of pyrolysis plant can be as follows: the reactor heats the raw materials to create oil gas. The oil gas then explores a condenser that converts the gas into liquid oil. This liquid oil can be used in vehicles as well as other industries as fuel. The oil gas that doesn't react from the condenser recycles in to the burner for one more cycle. This helps to ensure that the plant uses recyclable energy.

How does the pyrolysis plant work?

As mentioned above, worn-out tires and waste plastic are two of the main ingredients with this plant. The plant recycles these waste matter and produces fuel, thus saving natural resources significantly. Here's how the plant works:

1. Feeding raw materials

Step one would be to feed raw materials to the tyre pyrolysis plant having an automatic feeding machine. You have to keep a minumum of one-third in the reactor empty to allow the raw materials to rotate properly. Make sure the feeding machine's inlet closes tightly so the ingredients mix thoroughly.

2. Heating the reactor

Heating the reactor gently burns the raw materials inside. This step is crucial to converting the waste materials into combustible fuel. The reactor releases oil gas if the chamber reaches 100o C. Soon, the heavy oil gas separates by manifold and enters the condenser. Here the oil gas liquefies and drops into a huge oil tank. On the flip side, the lighter gas rises up into the oil condensers and liquefies in to the oil tank above. The non-condensable gas goes through a dedusting and desulfurization system, creating the furnace that connects towards the heat pyrolysis reactor for recycling.

3. Cooling down

The reactor cools down once it generates a batch of fuel oil. This enables the reactor to discharge carbon black automatically because the temperature falls below 40o C. If you are only using waste tires as raw materials, you need to use the steel wires out from the reactor using hooks if the temperature is in least 50o C or lower. More information on https://bestonpyrolysisplant.com/waste-tyre-pyrolysis-plant-cost/ here.

4. Purifying leftover gas

You may still need a compact amount of gas left inside the chamber. This gas is recyclable in the event you purify it by passing it using a smoke cleaning system. It helps to help make the gas satisfy the emission standards. Moreover, you hardly leave any waste if you are using every cubic meter of gas. This too allows you to prepare the reactor for your forthcoming batch. Leaving residues within the reactor and condenser may impact the next batch's production, thus reducing the fuel's overall quality.

A pyrolysis plant is probably the most crucial tyre recycling plant that help with keeping the environment clean. It recycles waste materials like tires and plastic to create fuel which you can use for a number of purposes.

Comments

Post a Comment