Everything You Should Understand About The Palm Kernel Shell Carbonization Machine

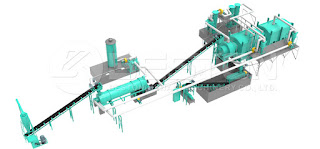

Living inside an area where palm trees are grown, you'll spot the large pile of palm shells that happen to be thrown or rather discarded at locations annually. Therefore, industry leading companies have developed and manufactured a number of state-of-the-art palm kernel shell carbonization machines. Our article features all the info you'll need to know about these machines as you turn waste into treasure.

Before palm shells are actually used, they are first checked as a way to determine whether they contain over 20% moisture. If for some reason they do, the shells are then dried in order to keep a special high standard as well as a finished product which is of exceptional quality. After drying, the shells are then conveyed to the carbonizing furnace by way of a belt conveyor for heating purposes. During the heating phase, extremely high temperatures are utilized but kept between 400 degrees C and 600 degrees C.

This process takes roughly fifteen minutes. However, at a specific temperature, tail gas develops and will be readily recycled throughout the system like a source of heat for the furnace. Next, the materials will then undergo a purification process together with a condensation process using the condenser system along with the spray dedusting system. After most of these the situation is done, your palm shells would have been changed into wood vinegar, charcoal and also tar. Click here to know more: https://bestonpyrolysisplant.com/straw-charcoal-machine/.

Additionally, this can be a type of renewable fuel. Consequently, the overall heating worth of palm shell charcoal is incredibly high and it is even smoke-free, clean and non-toxic. This particular item is also traditionally used within the animal industry, the pharmaceutical industry and of course the agriculture industry. The product is even made consumption of throughout the food industry as a way to obtain fuel for restaurants and like we mentioned before the agriculture field where it creates a much better soil quality.

With that said, there are still some things you must know about the entire process. Because of the varying organic composition in the different biomass elements, you're planning to find raw material with various numbers of moisture. So, it's best to be aware of that the technical final parameters aren't always the same. And your furnace temperature should not be below around 700 degrees C. More information on charcoal manufacturing machine here.

It's also good to learn that in case you're expecting a more substantial yield, your carbonization process is going to take place quite quickly. Hence, your general operating cost is going to be much lower than anticipated. And like we previously mentioned, your final product is used within various industries worldwide. Consequently, skilled professionals may also custom design plants to accommodate a user's demands.

With these machines, you can expect to experience a carbonization rate at roughly 4:1 or perhaps 3:1. This basically ensures that when you have one ton of raw dried material, you'll have the ability to produce 330 kg or charcoal. And because your material isn't always the same size, your end product will always vary.

While we conclude, we certainly have just investigated the palm kernel shell carbonization machine. These machines are manufactured to last and face the exam of their existence. So, investing may be your best decision yet! Visit the site: https://bestonpyrolysisplant.com/rice-hull-carbonizer/.

Comments

Post a Comment